Category

Recommended products

Automatic Five

Overview Automatic Multiple-layer PE Tube/Hose/Pipe Extrusion Line 1. B.JG-V Five-layer Full-plastic Tube Extrusion Tube

- Overview

- Product Description

- Tube Layers

- Sample Pictures

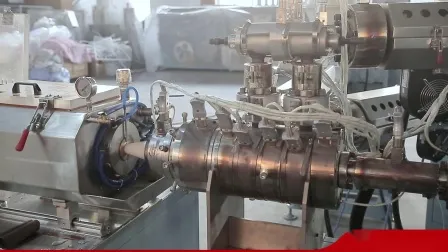

- Factory Pictures

- Processing workshop

- Contact

Basic Info.

| Model NO. | 100pcs/min |

| Type | Pipe Extruder |

| Plastic Processed | PE |

| Product Type | Extrusion Molding Machine |

| Feeding Mode | Multiple Feed |

| Assembly Structure | Integral Type Extruder |

| Screw | Multi-Screw |

| Engagement System | Intermeshing |

| Screw Channel Structure | Deep Screw |

| Exhaust | Don′t Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Welding Type | Hot Temperature |

| Speed | Changing According with Tube Diameter and Length |

| Transport Package | Wooden Case |

| Specification | 7000*5000*2200mm |

| Trademark | Sunway |

| Origin | Jiangsu, China |

| Production Capacity | 100 PCS/Month |

Product Description

Automatic Multiple-layer PE Tube/Hose/Pipe Extrusion Line

1. B.JG-V Five-layer Full-plastic Tube Extrusion Tube Machine

Material: LDPE / BA / EVOH / BA / LDPE Capacity: ≤110pcs / min Production speed: 12m-15m / min Tube Size: ∅19 ~ ∅60mm Installed power: 75kW Operating power: 50kW Equipment area size: 6500 (L) × 3500 (W) Voltage: 380V, 4P 50HZ Device Color: Gray (may be set according to customer requirements)- Extruder 1 (LDPE material extruded)

- Extruder 2 (LDPE material extruded)

- Extruder 3 (BA material extrusion)

- Extruder 4 (EVDH material extrusion)

- Co-extrusion die area

- Vacuum sizing tank

- Tractor

- Cutting Machine

2. B.ZJ-IV Four Heads Shoulder Injection Machine Mold Size Diameter (mm): 16, 19, 22, 25, 28, 30, 32, 35, 38, 40,50, 60 B.ZJ-IV Automatic Tube Shoulder/Mouth/Heading/Neck Injection Machine, researched and manufactured on our own, is a new type machine of advanced science and technology specially for shoulder injection. B.ZJ-IV Automatic Tube Shoulder/Mouth/Heading/Neck Injection Machines all operation is controlled by PLC of large-scale through a people-machine interface of touch screen. By plastic injecting, spitting, squeezing and welding, B.ZJ-IV Automatic Tube Shoulder/Mouth/Heading/Neck Injection Machine can make a plastic shoulder for plastic tubes and aluminum-plastic tubes. And the shoulder is smooth, beautiful and firm. B.ZJ-IV Automatic Tube Shoulder/Mouth/Heading/Neck Injection Machine mainly includes precise clearance apparatus, automatic tube-feeding device, fixed volume injecting device, plastic spitting device, mould-closing forming device, mould separating device, automatic tube-releasing device , automatic material-feeding device and cushion container. 3. B.ZFG-III Double-heads Screw Capping&Aluminum Foil Sealing Machine This machine is widely used in toothpaste, cosmetics, pharmaceutical and food industries, suitable for aluminum foil sealing and automatic screw cap of all kinds of aluminum-plastic laminated tube and plastic tube. The machine adopts gap dividing mechanism for circular rotary mechanism, precision gap inversion, and around it there are set following functions : automatic tube devices, aluminum foil sealing device, secondary heating sealing device, screw capping device, and secondary screw capping device. The above institutions and device is action under the control of PLC coordination .And in turn to finish the work of automatic tube feed, testing tube feeding condition, aluminum foil sealing, firstly screw capping, secondary screw capping, and tube out. Gap dividing mechanism adopts precision indexing CAM. Driven by motor. And motor speed controlled by the variable frequency. Reasonable distribution the working time of transposition and institution for each station. Transfer balance. And accurate positioning. Running speed can be adjust by the user, it can meet the general requirements of customer. 3.3.1 Inversion using precision protractor indexing CAM mechanism,Smooth operation3.3.2 Automatic to finish the work of double tubes feeding, capping , tubes out3.3.3 Transposition of motor using frequency to control of speed, and the speed is adjustable3.3.4 Screw cap is the servo motor drive, to ensure screw capping tightness.Through the replacement parts, it can be suitable for variety size of tube and cap. 4. B.SJ-1800 Cap Making Machine Mould Size Diameter (mm): 12.7, 16, 19, 22, 25, 28, 30, 32, 35, 38, 50, and 60 (Conical, nail, stand-up and flip top cap for choice)4.1 Introduction Injection moulding machine applies high responsive proportional variable pump system to replace the traditional 3-way proportional valve control mode , thus to enable the high match of power between hydraulic out put and machine effective operation which avoids energy loss from high pressure throttle , flow , compared with normal constant pump drive machine the variable pump drive machine is able to save . In addition , the machine less heating enables save of cooling water by 30% , debasing peripheral noise and extension of service life hydraulic sealing part sand oil to minimize operation and maintenance cost and meanwhile to meet the strict international environment protective policy finally , the amount of the output increases obviously. 4.2 Main Parameters

5. B.YS-6 Six-color Rotating Printer 4/6 Color Rotating Printer is based on advanced technical design of European countries,combined with practical experiences from tube factories.Being the best Choice of PE tube printing,it has stable quality and easy to operate and maintenance. Printing blanket unit,mandrel disk unit and oven can obtain the most reasonable in line speed by using individual motor and control constant speed by computer.There are three functions of this machine:printing,coating and drying separately or in line. It is most suitable for precise & clear printing.It also provide larger printing area & half tone jobs facility. For method of coating and drying,there are Regular Oven and UV Drying or both together for optional.

- Ink Unit Motor:5.5kw with Encoder,Inverter

- Mandrel Unit Motor:2.2kw

- Oven Unit Motor:2.2kw

- Ink Adjust Motor:150 w × 6 pcs

- Printing Ink:UV Ink

- Printing Plate:Copper,Zinc,Resin

- Corona Capacity:1 kw

- U.V.Dryer Capacity:4 kw,160 w/cm2

- Printing Dia: 19~50 mm

- Printing Length:200 mm(Max)

- Printing Speed:50~70 pcs/min

- Air Consumption:0.3-0.5mpa

- Power Consumption:53 kW

- Pin No.in Oven:948 pcs(7 Meter Oven)

- Machine Size:11500×1570×2150 mm

| Item. | Name and Model | Brand or Manufacturer |

| 1 | Variable speed motor:YVF2-132M-6 | Anhui Wannan Motor |

| 2 | High strength hardened gear speed reducer:ZLYJ146-10-II | Hangzhou Xiaoshan Shuguang Machinery Factory |

| 3 | Fan:DF-3 | Shanghai Zhangao Fan |

| 4 | Ball screw pair:SFE R 2525-6 D 470 | ABBA |

| 5 | Stainless steel pump:TPH2T3K | |

| 6 | Water circulation vacuum pump:2VB2 060-0NC00-2P | The German Siemens |

| 7 | Three-phase asynchronous motor deceleration:ZF32-0.75-30 | Xiamen Dongli |

| 8 | Servo Motor:MHMD082G1U | Panasonic |

| 9 | Servo motor drive:MCDHT3520E | Panasonic |

| 10 | Transducer:BFV00072Gk0.75kW | Panasonic |

| 11 | Frequency Transformer:AVF100-0754 | Panasonic |

| 12 | PLC:FP-X C30T | Panasonic |

| 13 | Touch Screen:PWS5610T-S | Hai Tai Ke |

| 14 | Vacuum pressure regulating valve:VC63 | Korea |

| 15 | Encoder:OVW2-20-2MHT 2000p/r | Panasonic |

| 16 | Screw arbor:Φ50 1:32 | Zhejiang Zhoushan |

1.4 Pictures 2.1 Introduction 2.2 Main Parameters

| Power Supply | 380V/50HZ |

| Power | 15kW |

| Air Pressure | 0.6Mpa |

| Air Consumption | 0.75m3 |

| Tube Diameter | Φ16-Φ50mm |

| Tube Length | 55-200mm |

| Productivity | 80-110pcs/min |

| Weight | 2500kg |

| Dimension(L*W*H) | 3.2m*1.4m*2.1m |

| Connection distributor(L*W*H) | 2.75m*0.5m*1.0m |

| Parts | Model | Manufacturer |

| Planetary reducer | ABR180-14-S2-P0 | TFO(Taiwan) |

| Planetary reducer | AB142-20-S2-P2 | TFO(Taiwan) |

| Planetary reducer | AB090-07-S2-P2 | TFO(Taiwan) |

| Planetary reducer | ABR090-30-S2-P1 | TFO(Taiwan) |

| Worm reducer | WPWDKS100-25-A | Jie brand |

| Vacuum generator | ZL212 | SMC |

| Air gripper (parallel opening and closing type) | MHZL2-25D | SMC |

| Vacuum suction cups and connectors | ZP3-T13BN-A5 | SMC |

| Main pneumatic components | AirTAC | |

| PLC | 6ES7512-1DK01-0AB0 | Siemens |

| touch screen | 6AV2123-2MB03-0AX0 | Siemens |

| Servo motor drive | 6SL3210-5FB10-8UF0 | Siemens |

| servo motor | 1FL6042-2AF21-1AA1 | Siemens |

| servo motor | 1FL6042-2AF21-1AB1 | Siemens |

| servo motor | 1FK2204-5AK01-1SA0 | Siemens |

| Servo motor drive | 6SL3210-5HE13-5UF0 | Siemens |

| servo motor | 1FK2210-3AB01-1SA0 | Siemens |

| servo motor | 1FL6092-1AC61-0AA1 | Siemens |

| Servo motor drive | 6SL3210-5FE13-5UF0 | Siemens |

3.4 Main Parameters

| power supply | 220V/50Hz |

| power | 1.5kW |

| Air consumption | 0.6m3/min |

| tube diameter | Φ19-Φ50 mm |

| tube length | 70-210 mm |

| production capacity | 60-110pcs/min |

| dimension | 2500×2000×1500 mm (L×W×H) |

| weight | About 800kg |

| Part | Model | Manufacturer |

| Chengbang Gear Motor | CH-4 1:20 1500W, 220/380V | Taiwan |

| Frequency converter | 6SL3210-5BE21 | Siemens |

| servo motor | 1FL6034-2AF21 | Siemens |

| Servo drive | 6SL3210-5FB10 | Siemens |

| touch screen | 6AV6648-0CC11 | Siemens |

| PLC | 6ES7288-1ST40 | Siemens |

| Speed motor | YN90-90, 90W, 220V (Vertical) | VTV |

| Curved cam indexer | RHH110F-8-120 | Shandong |

| Vibrating screen | Customized | Qigang Shanghai |

| Main pneumatic components | AirTAC |

| Model | B·JS1800×1 |

| Injection Unit | A B C |

| Screw Diameter mm | 40 45 48 |

| Screw L/D Ratio L/D | 23.6 21 19.7 |

| Shot Size(Theoretical) cm3 | 283 258 407 |

| Injection Weight(g) ps | 257 326 371 |

| Injection Weight(oz) ps | 9.1 11.5 13.1 |

| Injection Rate g/s | 122 137 150 |

| Plasticizing Capacity g/s | 185 21.7 23.8 |

| Injection Pressure Mpa | 215 169 149 |

| Screw Speed r/min | 200 |

| Clamping Unit | |

| Clamp Tonnage KN | 1800 |

| Toggle Stroke mm | 425 |

| Space Between Tie Bars mm | 460*460 |

| Max. Mold Height mm | 500 |

| Min. Mold Height mm | 180 |

| Ejector Stroke mm | 130 |

| Ejector Tonnage KN | 45 |

| Other | |

| Max. Pump Pressure Mpa | 16 |

| Pump Motor Power kW | 15 |

| Heater Powder kW | 9.3 |

| Machine Dimensions(L*W*H) m | 5.2*1.35*1.9 |

| Machine Weight(Appoximat) t | 5 |

- For UV lacquer,special UV oven is required,with which to obtain rapid drying out and more glossy surface.We also offer UV & heater oven in common which can save space and easy to operate and save energy for our customer to choose accordingly.

- Precise index ensures accuracy of every movement.It is easy to dismount/rectify printing mandrel.

- Tube feeding system works with detector.Coating will not be proceed without tube on mandrel.Machine will stop automatically if tubes are not taken from mandrel to the oven.

- Corona system with precipitator ensures cleaning of tubes before printing.

- Reasonable ink-transmission system shows good effect to large area/screen point printing.

- Foldable ink unit is easy to clean,change color and stick printing plate.

Tube Layers

Sample Pictures Factory Pictures Processing workshop Contact